| Unlike the typical

pen depicted in Part

I, the Vacumatic has a section that screws into

the barrel. The nib and feed are pressed into the section.

In addition, a breather tube is inserted into a hole drilled

into the back end of the feed, and a smaller hole is drilled

to connect the breather tube with the feed’s air

channel. This system allows an unimpeded flow of air to

the back end of the barrel, and it also provides the path

through which ink is drawn into the pen when the filler

is operated. |

|

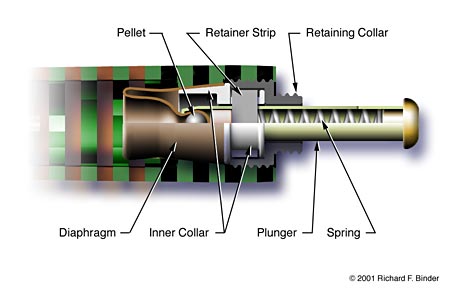

| The Filling

System: The next figure shows a larger view of

the Vacumatic’s unique and revolutionary filling

system. Although Parker advertised the Vacumatic as having

no rubber sac for ink storage, the pen nevertheless does

have a rubber diaphragm. The diaphragm is exposed to the

ink supply, and — like a sac —

can ossify. |

|

| The diaphragm

is deeply cup-shaped, with a small pocket at its closed

end. In the pocket is a small pellet of hard rubber or

plastic. To install the diaphragm, a small tool is used

to push the pellet into the hole at the end of the tubular

aluminum plunger. The rubber of the diaphragm is stretched

so that it will fit through the hole, which is just small

enough to keep the pellet from popping out when the rubber

is not being stretched. The open end of the diaphragm

is then folded back and fitted around the tapered portion

of the inner collar. No adhesive is required. |

|

|

|

| After the diaphragm

is in place, the filler unit is inserted into the back

end of the barrel and secured by the retaining collar.

This step is also performed without adhesive. Because

the retaining collar is threaded at both ends, it must

be tightened with a special tool that screws onto the

threaded portion that will remain exposed. This threaded

portion receives the blind cap. |

|

| The retainer

strip passes through slots in the inner collar and the

plunger, to provide a stop against which the spring rests.

The retaining collar secures the inner collar in place

and also prevents the retainer strip from sliding sideways

and coming out of its slots. The pinkish plug (not called

out) is a relatively tight fit into the plunger; it is

blocked by the retainer strip and forms a cushion for

the diaphragm where it is compressed by the pellet. |

|

| Depressing the

plunger compresses the spring and distends the diaphragm

to drive air out of the barrel. Releasing the plunger

allows the spring to extend, relaxing the diaphragm to

draw ink in through the breather tube. |

|

| Differences

Through the Years: The original Vacumatic filler

is like the Speedline filler except that there are notches

cut on the sides of the slots in the plunger. These notches

are at the outer end. By depressing the plunger and turning

it slightly clockwise, the user locks the plunger in its

depressed position. |

|

| Beginning in

1942, Parker used a redesigned filler in order to conserve

critical war matériel. This newer filler is much

simpler in design. It has a plastic plunger that is smaller

in diameter than the aluminum plunger. The spring in the

newer model is fitted outside the plunger. It is attached

to the plunger at the end nearest the diaphragm, and its

other end is made so that it rests on the back end of

the inner collar. Depressing the plunger stretches this

spring. Some late Vacumatic and Duofold models have fillers

whose retaining collars are made of plastic instead of

metal; these plastic retaining collars are softer and

sometimes cannot be removed and reinstalled without being

destroyed. |