|

December, 2002

Recently I had the opportunity to go to the port town of Wajima, home of the world famous "Wajima nuri" style of Japanese lacquerware. Recently I had the opportunity to go to the port town of Wajima, home of the world famous "Wajima nuri" style of Japanese lacquerware.

I flew with a party from the Nakaya Fountain Pen Company from Tokyo to Komatsu Airport in Ishikawa-ken. There we met the vice president of one of the companies in Wajima which produce the "urushi" lacquerware, including "maki-e" products.

This company has been producing Nakaya's new line of urushi fountain pens, and the purpose of this trip was to observe first hand the production of these beautiful pens.

If you would like to know more about urushi, and Wajima, and "Wajima nuri," I have written a separate background article that describes what urushi is and where it comes from, and how to take care of it so that it will last for many generations. There is also more information there on the town of Wajima.

We drove another two hours from the airport through the crisp winter air to the old port town of Wajima on the coast of the Sea of Japan

Our first stop was a factory which produces wooden objects for lacquering. Our first stop was a factory which produces wooden objects for lacquering.

The wood used in Wajima nuri is a special wood called Keyaki. This wood is very porous, and is carved so thin that you can see light shining through the tiny "pores" in the surface. The lacquer on the outside surfaces actually flow through these tiny holes and join with the lacquer on the inside surfaces to form a very strong bond. This refers only to the wooden lacquerware objects such as bowls and cups. The urushi fountain pens produced in Wajima are made of ebonite (hard black rubber).

This wood is seasoned in a smoke room for at least a week to ten days before it can be made into lacquerware.

The whole building had a nice smell of wood smoke, and there were mountains of wooden bowls in every room, and on the stairwells.

We talked to the craftsmen and watched them work on their lathes. We talked to the craftsmen and watched them work on their lathes.

There were thousands of templates hanging on the walls for all the varieties of bowls and objects produced for different companies, and the elaborate system of identification was all in the craftsmen's heads!

After we left the wood factory, we went on to visit the place where urushi lacquerware including the Nakaya urushi pens are produced. In this building the urushi craftsmen work on one floor and the maki-e artists work on another floor.

First, Mr. Yoshida prepares a thin coating of urushi |

First we met Mr. Yoshida who lacquers the Nakaya urushi pens. I was very glad to finally meet him as he is the man who produced my own prized Nakaya tamenuri pen. I showed him the pen and he recognized it as one of his relatively earlier models.

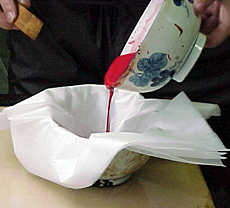

Mr. Yoshida demonstrated the urushi pen creation process from beginning to end. First he took a bowl of black urushi and poured it into some kind of filtering paper which he wrapped by twisting both ends. He the put the paper and its contents onto a wooden wringer which he hand cranked to twist the paper and force the thick oozing urushi through the paper and into a bowl. This strains out inpurities and hardened urushi.

Next he spread out a thin transparent layer of urushi on the glass surface of his table and brushed it onto the surface of the ebonite pen barrel. This removes dust from the surface of the pen.

He the dipped a different brush into the urushi and began to coat the pen in earnest with the swift, deliberate strokes of a well seasoned craftsman.

Urushi is very thick and sticky, and leaves a very clear trail of bubbles and brush strokes behind the stiff brush bristles. But these ridges and bumps completely vanish within a few seconds, leaving a perfect unbroken reflection on the surface -- absolutely beautiful!

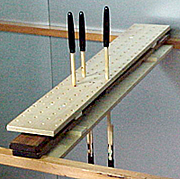

Mr. Yoshida then put the pen with its holder (a chopstick) onto a hardening board which he puts on a rack. He the inverts the board periodically to allow even hardening with no thick or thin spots. I am trying to avoid using the word "drying" because urushi does not dry; there is no evaporation involved. It actually hardens by a chemical reaction with the air and moisture. (See my article on urushi for more information). Mr. Yoshida then put the pen with its holder (a chopstick) onto a hardening board which he puts on a rack. He the inverts the board periodically to allow even hardening with no thick or thin spots. I am trying to avoid using the word "drying" because urushi does not dry; there is no evaporation involved. It actually hardens by a chemical reaction with the air and moisture. (See my article on urushi for more information).

After a week or so, after the surface has hardened, it will get a good burnishing and another coat of urushi, and yet another burnishing and coating a week after that.

Next, Mr. Yoshida demonstrated the red urushi process, beginning with the wringing and straining of a bowl of red colored urushi.

Pouring the red urushi into a filter for straining out impurities |

Wrapping the paper tightly around the urushi |

The wooden wringer |

Finished |

The striking contrast between the black ebonite and the bright red urushi

The striking contrast between the black ebonite and the bright red urushi|

This process is the same as the black urushi except that in later coatings, some red urushi pens will be coated with black or natural brown urushi to produce the beautiful"tamenuri" effect, where the finish resembles a wet pool with the red bottom surface reflecting up through translucent layers of brown or black. This effect actually increases and becomes more beautiful with time.

For photos of how tamenuri urushi changes with time, see Nakaya's tamenuri Web page.

The brush strokes are clearly visible while the urushi is being applied.

The brush strokes are clearly visible while the urushi is being applied. |  They soon vanish, leaving a beautiful unbroken surface.

They soon vanish, leaving a beautiful unbroken surface. |

Some newly finished briar pen barrels |

We then went to a different room where briar pens were being lacquered.

There, our host had a surprise for us. He demonstrated a lacquer and burnishing technique on the surface of a briar pen which darkened and brought out all the beauty of the wood grain while protecting it in a hard shiny urushi coating. The results were amazing and quite different from any briar pen we had seen in the past. They resembled high quality polished briar pipes. You can expect an announcement some time next year concerning a new line of Nakaya briar pens with this new finish.

I was then asked if I wanted to try my hand at applying urushi to a Nakaya briar pen. I was very eager to do so since I am am hoping to acquire one these briar pens some day, and such a memory would make the experience of owning one that much sweeter. Of course with briar pens, the coating of urushi is thin to allow the natural grain of the wood to show through. It is applied with a piece of cotton gauze rather than a brush. I held the cotton very carefully so as not to get any urushi on my fingers. The active ingredient in urushi which gives it its legendary toughness is the same ingredient that puts the itch in poison ivy! I was then asked if I wanted to try my hand at applying urushi to a Nakaya briar pen. I was very eager to do so since I am am hoping to acquire one these briar pens some day, and such a memory would make the experience of owning one that much sweeter. Of course with briar pens, the coating of urushi is thin to allow the natural grain of the wood to show through. It is applied with a piece of cotton gauze rather than a brush. I held the cotton very carefully so as not to get any urushi on my fingers. The active ingredient in urushi which gives it its legendary toughness is the same ingredient that puts the itch in poison ivy!

I had great fun applying the urushi although the expression on my face in the photo might not show it! That's a look of concentration. Really!

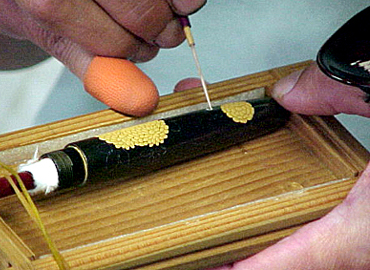

We next visited the maki-e production room where two artisans were applying their craft. Since all the work is done sitting on a tatami floor at low tables, the lamps hanging from the ceiling were at about chest level when we walked in the door! We next visited the maki-e production room where two artisans were applying their craft. Since all the work is done sitting on a tatami floor at low tables, the lamps hanging from the ceiling were at about chest level when we walked in the door!

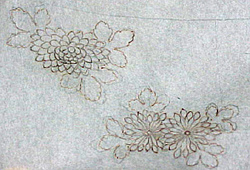

In the maki-e process, the artist first draws an intricate design on a thin piece of paper with a very sharp pencil. The he takes a very thin brush and traces over the pencil lines with urushi on the reverse side of the paper. He then presses the paper to the pen and lightly dusts some white powder on the wet urushi to make the lines visible. He then proceeds to paint in the pattern with more urushi. This urushi is sometimes tinted with yellow or red or some other color. Eventually the urushi will be covered with gold powder, but the gold will still be influenced by the underlying color of the urushi. Some common tints include ao-kin and aka-kin (blue gold and red gold). In the maki-e process, the artist first draws an intricate design on a thin piece of paper with a very sharp pencil. The he takes a very thin brush and traces over the pencil lines with urushi on the reverse side of the paper. He then presses the paper to the pen and lightly dusts some white powder on the wet urushi to make the lines visible. He then proceeds to paint in the pattern with more urushi. This urushi is sometimes tinted with yellow or red or some other color. Eventually the urushi will be covered with gold powder, but the gold will still be influenced by the underlying color of the urushi. Some common tints include ao-kin and aka-kin (blue gold and red gold).

Maki-e artist brushing yellow tinted urushi on top of the stanciled design. Notice the special pallet (tsume ban) attached to his thumb. |

Close up of the intricate pattern |

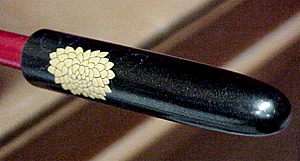

The finished flower design awaiting the gold sprinkling. The delicate outlines of leaves yet to be painted are faintly visible.

The finished flower design awaiting the gold sprinkling. The delicate outlines of leaves yet to be painted are faintly visible. |

After the design has been painted, while the urushi is still sticky, he sprinkles fine gold powder onto the urushi through a bamboo tube. This gold powder can be as fine as flour. For more information and photos on the gold sprinkling process, see my article on a visit with two maki-e artists.

Although Nakaya has not officially announced its new line of maki-e pens as of this writing, it is obvious that they are planning to do so, since we have photographs of these artists actually producing the pens. From what I heard and observed, it appears that there will be both regular and togidashi maki-e pens. Togidashi is the process of building up alternate layers of gold powder and dark urushi and then polishing back the urushi to let the gold shine through. The resulting effect is the appearance of sparkling objects partially submerged in a dark pool.

We spent two days in Wakajima, and had a great time, and got to meet some great people who take a lot of pride in their art. I believe the entire group came away inspired and excited about the new fountain pens that will be coming out of this small and famous town in the months ahead. And I've got a longer pen wish list now, including a few models that don't officially exist yet!

|