|

Rattling Lever in Sheaffer Pen

Mike Walton asks: I recently put a new sack in a Sheaffer triumph-nib 1000 lever filler. The pen fills and functions well, but the lever is loose when in the closed position; it pivots about 1/8” and rattles when the pen is shaken. The pressure bar appears to be in good shape and tight to the barrel, though I have not taken it out of the pen yet. There is a bulge in the barrel where the lever ring is. My first question is what can be done about the lever, and second, can I eliminate the bulge?

The simplest thing to check is whether the pressure bar is really tight. This entails removing the pressure bar because Sheaffer pressure bars are compound bars but are made in one piece. (See the photo at right.) The center “tongue,” which runs from the front to the back, is the pressure bar, and the side tails are the spring. The tongue is the critical part, but it isn’t the barrel that it needs to be tight against; rather it‘s the lever itself. You may need to try a couple of different bends, but the best results usually happen when the bar is straight and aligned properly. The simplest thing to check is whether the pressure bar is really tight. This entails removing the pressure bar because Sheaffer pressure bars are compound bars but are made in one piece. (See the photo at right.) The center “tongue,” which runs from the front to the back, is the pressure bar, and the side tails are the spring. The tongue is the critical part, but it isn’t the barrel that it needs to be tight against; rather it‘s the lever itself. You may need to try a couple of different bends, but the best results usually happen when the bar is straight and aligned properly.

But there is, as you may have surmised, more to it. The lever itself can be a problem if its short end, where it bears against the pressure bar, is worn. A badly worn lever will have a pronounced rounding-off where it rubs the pressure bar. (See image at left.) If it is worn, it may not bear fully on the bar, and this can cause a rattle. But there is, as you may have surmised, more to it. The lever itself can be a problem if its short end, where it bears against the pressure bar, is worn. A badly worn lever will have a pronounced rounding-off where it rubs the pressure bar. (See image at left.) If it is worn, it may not bear fully on the bar, and this can cause a rattle.

I’ve saved the worst for last. That barrel bulge you noticed can be, and probably is, the root of your problem. When the barel is bulged in this way, the lever is not seated as far into the barrel as it should be, and it doesn’t bear on the pressure bar. It’s possible to remove the bulge, but it‘s risky. You need to remove the lever and then apply carefully controlled heat to the barrel. The idea is to soften it just enough that you can gradually reshape it back into its original perfectly cylindrical shape; but it is not easy. Soften it too much, and you end up with a worse problem; soften it not enough, and nothing happens. Even with just the right amount of heat, you can still mess it up; among other pitfalls is the possibility that the groove into which the lever clip ring fits will simply collapse and leave a groove around the outside surface of the pen. If you do manage to get the bulge out, you should make a new clip ring using spring wire 0.005" smaller in diameter than the original to reduce the probabilty of a bulge in the future.

Converter Interchangeability?

eilu asks: I recently wanted to purchase a Rotring Newton, but alas, there are no Rotring converters available here (Philippines); while Rotring converters seem available online, I cannot afford the costs due to the dollar exchange rate (more than 50 local currency to a dollar). Are converters interchangeable between brands? Parker is one of the (if not the only) brand that has converters that are readily available.

There are some swaps that work; for example, many Italian pens uses an off-the-shelf Schmidt converter, but in general, converters are not universally interchangeable. Unfortunately, Parker converters don’t fit rOtring pens. Do you have a correspondent in Europe or the USA who could buy a converter for you and send it in a personal mail? There are some swaps that work; for example, many Italian pens uses an off-the-shelf Schmidt converter, but in general, converters are not universally interchangeable. Unfortunately, Parker converters don’t fit rOtring pens. Do you have a correspondent in Europe or the USA who could buy a converter for you and send it in a personal mail?

Pelikan Nib Skips — Easy to Fix?

Terry Mahoney asks: Somewhere I heard that Pelikan is out-sourcing their nibs and now they are having a problem with skipping. I recently bought a new Pelikan 400 with a broad nib. It skips when starting unless I use a lot of pressure. I am relatively capable of fixing things. Could you please tell me how to fix this problem.

Unfortunately, the behavior you’re experiencing can occur with any nib and is not the problem that I’ve traced to Pelikan’s recent nibs. The nibs affected by that problem, about which I wrote in an earlier column, are the M800 and M1000. Your pen’s nib could need its tines respaced farther apart, or realigned, or twisted to align the slit walls; or it could need its tip reshaped, as some Pelikan nibs have what I call the “butt cheeks” problem. (See the image to the right.) This problem occurs when the edges of the slit are too rounded; you get great smoothness, but the rounded edges don’t allow the ink to come down to the paper unless you press hard enough to force paper up into the slit. I wish I could give you a silver bullet here, but fixing your nib will require analyzing it to see which of these problems is causing its failure. (Be aware that any given nib can have more than one problem!) Unfortunately, the behavior you’re experiencing can occur with any nib and is not the problem that I’ve traced to Pelikan’s recent nibs. The nibs affected by that problem, about which I wrote in an earlier column, are the M800 and M1000. Your pen’s nib could need its tines respaced farther apart, or realigned, or twisted to align the slit walls; or it could need its tip reshaped, as some Pelikan nibs have what I call the “butt cheeks” problem. (See the image to the right.) This problem occurs when the edges of the slit are too rounded; you get great smoothness, but the rounded edges don’t allow the ink to come down to the paper unless you press hard enough to force paper up into the slit. I wish I could give you a silver bullet here, but fixing your nib will require analyzing it to see which of these problems is causing its failure. (Be aware that any given nib can have more than one problem!)

Tightening a “51” Clip

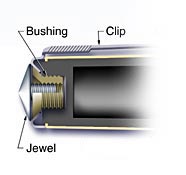

Wes Simpson asks: I found a nice 51 with a gold filled cap. The clip is loose and rotates freely around the cap. I am thinking that there is a screw beneath the “jewel” which can be tightened. I wonder if you can tell me if this is correct and if so, how do I get that darned “jewel” out without ruining it?

You are right in thinking there is a screw under the jewel. As you can see from the image here, the jewel screws into a brass bushing that screws, in turn, into the inner cap. Before you start trying to remove anything, wrap cellophane tape around the cap, sliding it under the clip ball, to keep the clip ball from scoring a groove or bright strip in the cap’s finish. You are right in thinking there is a screw under the jewel. As you can see from the image here, the jewel screws into a brass bushing that screws, in turn, into the inner cap. Before you start trying to remove anything, wrap cellophane tape around the cap, sliding it under the clip ball, to keep the clip ball from scoring a groove or bright strip in the cap’s finish.

To remove the jewel, use a square of very firm rubber about 1" square and about 1/8" thick. With the ball of your thumb, press the rubber against the jewel and turn with a sharp counterclockwise motion. The jewel may come loose so that you can screw it out. But it probably won’t; these babies can be very temperamental. You can try soaking, ultrasonic cleaning, and heat to loosen the jewel. All of these methods are likely to require patience, so be prepared to sit in for the long haul. Heat will be required if the jewel is still secured as it was from the factory, by shellac. Be careful how much heat you apply, because the jewel is celluloid, not acrylic, and it will begin to soften at about 165° F. (Shellac softens at about 140° F.)

Sometimes the jewel brings the brass bushing with it. If this happens, grasp the bushing endwise using serrated-jaw needlenose pliers and heat the bushing, turning it around as you do, so that the heat will reach all sides. Try to keep the jewel itself out of the heat. Try every half minute or so to unscrew the jewel. it may come a little bit at a time, requiring several heatings.

Once you have the jewel out, you can use a wire brush to clean shellac residue from its threads. Cleaning shellac out of the brass bushing will require a dental pick and patience.

You can now screw the brass bushing in tightly. (If the inner cap turns freely, put the cap on the pen so that friction with the hood will keep the inner cap from turning.) Be careful to check whether your pen has a Split Arrow clip or a plain Arrow clip. If it has a plain Arrow, then there is probably a raised “tab” that fits under the clip to keep it from turning when the brass bushing is tight. After the bushing is tight, screw the jewel back in. Usually, seating the jewel with a firm twist of the rubber square will keep it in place nicely. Shellac it if you must.

Email your question to the Pen Doctor! |

Questions will be answered only through this column on the Pentrace Web site. We regret that time does not permit the Pen Doctor to give a personal reply to every question. |

|