| Although I’m in the business of repairing and

restoring fountain pens, I’d be silly to ignore the fact that

some collectors are eager not only to use, but also to maintain and

even repair their pens. Replacing a leaking, ossified, or otherwise

dead sac is among the simplest and most straightforward repairs you

can make, and I know from experience that it's tremendously

satisfying to start with a pen that won't take ink and end with one

that does. This article, then, is my way of sharing that pleasure

with you.

It’s always a

good idea to learn by practice rather than waiting until a precious

pen is on the line. To this end, I suggest you buy a couple of cheap

pens on eBay or at your local flea market or antique mall to teach

yourself the ropes before you turn your attention to your minty red

ripple Waterman’s Ideal No. 7 with the Blue nib. Arnold,

Wearever, Epenco, and Tuckersharpe are some cheap names to look for,

and there are countless no-name junkers that go for less than $10.00.

(I use the term “junkers” loosely, as you already know if

you've read Don Fluckinger’s recent Extra Fine Points series on these pens.) If you get pens

that have sacs, you can easily rip ’em out. This, too, is part

of learning to resac a pen.

Tools and Supplies

First, you need a supply of sacs. No problem. Shown

here, from top to bottom, are No. 13, No.

16 (latex and silicone), and No. 22 straight

sacs. At the bottom, for reference, are a Debutante Vacumatic

diaphragm and a standard Waterman Ink-Vue sac.

My sac vendors of choice are the Pen Sac Company and

Wood Bin Ltd. (Contact information for all the suppliers I mention is

at the end of this article.) The Pen Sac

Company sells a bewildering variety of straight sacs, necked sacs,

tapered sacs, Ink-Vue sacs, and Vacumatic diaphragms.

(“Diaphragm” is what Parker called the rubber doohickey

in a Vacumatic so they could advertise the pen as being sacless.)

They offer a couple of assortments as well as individual sacs. Their

catalog includes several pages of information showing which sacs go

into which pens. (There may be exceptions on a per-pen basis; the

catalog says to use a No. 21 necked sac for a hard-rubber Duofold

Junior, but I couldn’t even get a No. 20 to fit into the barrel

of a Junior I resacked some time ago.) Wood Bin Ltd offers a smaller

variety, but Wood Bin also sells straight sacs made of silicone.

Silicone is sometimes a better choice than latex because it

doesn’t outgas sulfur vapor that can cause some celluloids to

turn brown.

You can also buy

sacs from Fountain Pen Hospital, Pendemonium, and others; and Pen Sac

Company and Wood Bin Ltd will of course be happy to sell you one or

two sacs.

Next, you need sac

cement. Some pen suppliers can sell you sac cement; several of the

vendors I list here offer small bottles with an applicator brush for

about $5.00. Being a professional cheapskate, I ran down to my local

paint store and handed over about five bucks for a half-pint can of

orange shellac, which is what the pen companies themselves used. I

have enough shellac to last until my 273rd birthday. On the other

hand, I don’t have that nice applicator brush, so I have to

resort to subterfuge. I use toothpicks.

Steal your

spouse’s talcum powder, but make sure that it is 100% pure

talcum powder. Do not use baby powder or ladies’ dusting

powder, or any powder that contains fragrances, cornstarch, zinc

oxide, or other additives! These products are oiled to protect

delicate skin, and oil eats rubber. Pen sacs are rubber... If

there’s no plain talcum powder in the house, go buy a can. (I

should point out that pure talcum powder is very hard to find these

days; your best bet may be from a billiards supplier.) If you

absolutely cannot find talcum powder, you can substitute powdered

graphite. This stuff is sold by hordware stores and locksmiths for

lubricating locks and other mechanisms that are exposed to cold and

wet. It's messy, but it does work.

The last pen-geek

item you’ll need is section pliers. Many pens

— most, really — don’t call for

the big guns, so you may not need section pliers immediately. When

the time comes, you can buy very good ones from Fountain Pen Hospital

(shown here) or from Father Terry Koch.

Note that the Fountain Pen Hospital pliers shown here

are actually intended by their manufacturer, K–D Tools, for use

on automobile spark plug wires. You may be able to find them for a

lower price at an auto parts store.

If you have a bench grinder, you can make your own

section pliers out of garden-variety slip-joint pliers from a

hardware store and some rubber fuel-line tubing from an auto parts

store. If you go this route, you’ll need two pieces of tubing,

each about an inch long, of a size to slip securely over one jaw of

the pliers. Grind the teeth off the concave serrated part of the

jaws, leaving a smooth curve, and slip one rubber onto each jaw.

Position them so that they cover the part of the jaws that you ground

smooth; that’s the area in which you’ll grip a

section.

This is exactly the way Father Terry makes his section

pliers, and to be quite frank, I bought a pair from him rather than

expend the effort to make them.

Okay, you have the

tools (with one possible afterthought, of which more below). Sit

yourself down at a well-lighted table or desk, and we’re

off.

Disassembly, Cleaning, and Sac Removal

The first job is to get the old sac out. This means

taking the pen apart. Most pens have a section that is a slip

friction fit (just pushed into the barrel), but some (notably button

fillers, Touchdowns, and Snorkels) have a threaded section that

screws out. Virtually all lever fillers, except a few early

Sheaffers, are a slip fit. For simplicity, I’m going to

describe only the typical slip-fit lever filler in this article. (If

you decide you like this kind of work, get a copy of “Da

Book,” Frank Dubiel’s indispensable guide to fountain pen

repair, and let Frank show you how to handle the more esoteric pens.)

First, try using

your fingers to rock the section gently back and forth sideways,

pulling as you rock, to break it loose. Don’t rock too far or

you risk cracking the barrel!

If it refuses to budge, it’s probably shellacked

in place. (Sheaffer shellacked visulated sections but not hard rubber

ones, for example.) You can resort to section pliers. Grasp the

barrel firmly in your closed fist. (You can enhance your grip by

using a rubber kitchen jar-lid gripper.) With the other hand, apply

the section pliers to the section, and repeat the rocking/pulling

action, twisting a little as if to unscrew the section. If it’s

a slip-fitter, it’ll come loose unless it’s been

shellacked in place, or possibly even glued (as on Waterman’s

Taperite from the 1940s). In that case, you’re better off

leaving it to a professional. Yes, I know, you just blew the price of

a pen on tools. Use them on the next pen.

With the section loosened, you should be able to work

it gently out of the barrel. Use your fingernails or a sharp kitchen

knife to scrape all remaining fragments of the sac from the end of

the section (the nipple). You need to get the nipple as clean as

possible so the new sac will adhere properly. You can use your knife

to scrape off the shellac that is probably there, and you can use

rubbing alcohol as a solvent for this operation. But don’t use

alcohol on a visulated section; the plastic used for visulated

sections is likely to be soluble in alcohol!

This is your opportunity to do your pen a favor by

giving it a thorough cleaning. Drop the section assembly into a bath

of diluted clear household ammonia for five or ten minutes. Make your

solution by mixing 1 tablespoon (15 cc) of ammonia with

2/3 cup (160 cc) of water. After soaking

the parts, scrupulously clean off any ink residue and the cleaning

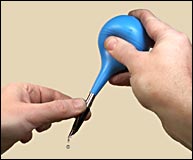

solution. This means flushing water through the system, which you can

do by using an ear syringe to force water through the section from

the sac end. (If you don’t have an ear syringe, you can use

your mouth for this job.) When the assembly is clean, dry it

thoroughly; blow some air through to dry the inside.

Clean the cap the

same way, paying particular attention to getting the ink out from

inside the cap. One way to do this is to use a paper napkin. Twist

one corner of the napkin into a long thin spear, and insert it into

the cap with a screwing motion. Turn in the direction that will keep

the twist tight. Drive the paper as far down as you can get it.

Repeat as necessary.

Now, if the sac

didn’t come out in one piece, extract its remains from the

barrel. A long thin alligator pliers, such as you can get from Wood

Bin Ltd, Fountain Pen Hospital, or Widget Supply, can be helpful here

but isn’t a necessity. If the sac is ossified, you can probably

just dump out the chips. Occasionally you’ll run into a sac

that has managed to glue itself, whole or in pieces, to the inside of

the barrel. This can get ugly. I use various

“afterthought” tools such as dental picks and scalers to

chisel pieces of sac away from barrel walls. You can get dental picks

from Wood Bin Ltd or Widget Supply. I find scalers very useful, and I

get them from KV Vet Supply. Take your time; as with the nipple, you

want to get the barrel clean. Be careful not to damage the filler

assembly.

If the old sac died and dumped ink all over the inside

of the pen, clean the barrel, too. You may also find that using your

soaking solution on a barrel will make it easier to extract glued-in

bits of sac. Get the barrel absolutely dry afterward; any moisture

left inside can corrode the parts of the filling assembly.

Sac Selection and Installation

With everything clean, you’re finally ready to

install a new sac. If you don’t know the right size, try

different sizes (you bought the assortment, right?) until you find a

sac that just slips snugly into the barrel with the filler assembly

in place. Then choose a sac two numbers smaller; if a No. 18 fits

snugly, use a No. 16. You need to leave air space between the sac and

the barrel to keep the pen from transferring your body heat into the

sac when the pen is in your pocket. If the sac gets warm, the air in

it expands, and it can force ink out through the feed. This makes the

inside of the cap very messy, which is why you just cleaned it. No

matter what sac size you end up with, it needs to be a stretch fit

over the nipple. If you’ve chosen too small a sac, you may have

to go up one size. You can try stretching the end of the sac over the

nipple to verify that it’ll go.

The sac needs to be

the right length. Most sacs are “straight” sacs; that is,

the diameter of the sac is the same along its entire length. Sacs are

made much too long; you will need to cut your new sac to the right

length. To find how long it should be, slide it into the barrel,

closed end first, until it hits bottom. Slide it back out about

1/8” (3 mm) so that it won’t butt against the end of the

space into which it fits. Clamp it with your thumbnail right where it

enters the barrel, and pull it out.

Still clamping it, hold it up to the section, lining

your thumbnail up with the step on the section that seats against the

end of the barrel. Now mark the point on the sac that corresponds to

the step between the nipple and the part of the section that fits

into the barrel. This distance will be between 1/4” (6 mm) and

1/2” (13 mm). In the illustration here, you can see a bright

line where light is reflecting off the step between the nipple and

the rest of the section.

Cut the sac at this point, being careful to cut

straight across.

If your pen requires a necked sac (with the open end

smaller than the diameter of the rest of the sac, like the neck of a

bottle), you must rely on the information in the Pen Sac catalog or

else measure the space into which the sac fits and then choose a sac

of the proper length. You don’t cut necked sacs; they have to

fit right. This may mean that you can’t order the exact sac you

need until you’ve taken the pen apart.

With the sac ready

to install, apply a small amount of sac cement (shellac) around the

outside of the nipple. Be careful not to let the cement get into the

inside; it’ll clog the feed — possibly

permanently! Spread the open end of the sac, stretch it over the

nipple, and adjust it so that it’s pushed all the way down and

is seated against the step. If you find that you’re a little

clumsy and have trouble fitting the sac in place, you can buy a sac

spreader. Pendemonium offers these little gems for $5.00. I recommend

that you buy yours yesterday, as today — with wet

cement drying on your pen — isn’t the best

time to go shopping. The sac should stand straight up, in line with

the section, and the stretched part should be symmetrical on all

sides. (The sac shouldn’t be pulled over toward one side of the

nipple.) If you like, you can run a very small bead of cement around

for an improved seal right where the sac butts against the step.

Once the sac is installed properly, put the assembly

down. Go away for half an hour to let the cement dry. It

doesn’t necessarily take half an hour, but if you adhere to a

firm half-hour waiting period, you’ll never proceed too soon.

Getting itchy and proceeding too soon means having a still-wet sac

come off in your hands or leak in the pen or —

worst of all — glue itself inside the barrel.

Now cover the new sac with a thin coat of talcum

powder (or graphite). This will make it slide into the barrel more

easily, and the filler will also work a little more smoothly.

Reinstall the section into the barrel, aligning the lever with the

nib as you go. (Some pens, mostly English brands such as Conway

Stewart, usually have their levers aligned on the underside, 180°

away from the nib surface.) There’s no need to cement a hard

rubber or ordinary plastic section in place unless it’s close

to falling out, but Sheaffer has always recommended that visulated

sections be shellacked in. If your section is so loose that it really

does fall out, try shimming it with a bit of paper.

Et le

voilà! You’ve just accomplished a task that used to

require the services of a highly paid professional. You’re on

the road to restoring your way to a better pen collection. Fill your

revitalized pen and enjoy the ride!

Resources

Fountain Pen Hospital

10 Warren Street

New York, NY 10007-2218

USA

Phone: 212-964-0580

Toll-free: 1-800-253-PENS

Fax: 212-227-5916

Web site: http://www.fountainpenhospital.com/

Email: fountainpenhospital@att.net

Pendemonium

Phone: 319-372-0881

Fax: 319-372-0882

Web site: http://www.pendemonium.com/

Email: info@pendemonium.com

Father Terry Koch died in May 2004, and his tools are

now available from Victor Chen.

Email: vwchen@pacbell.net

The Pen Sac Company

P. O. Box 4470

Carlsbad, CA 92018-4470

USA

Phone: 619-729-6894

Toll-free: 1-888-PENSACS

Fax: 619-931-5845

Web site: http://www.pensacs.com/

Email: PenSacs@aol.com

Wood Bin Ltd.

R.R. # 6, Simcoe

Ontario

Canada N3Y 4K5

Phone: 519-428-2555

Fax: 519-428-6311

Web site: http://www.simcom.on.ca/woodbin/

Email: woodbin@simcom.on.ca

Widget Supply

P. O. Box 3282

Albany, OR 97321-0710

USA

Fax/Voicemail: -541-924-8882

Web site: http://www.widgetsupply.com/

Email: widget@proaxis.com

KV Vet Supply

3190 N Rd

David City, NE 68632-5142

Phone: 800-423-8211

International: 402-367-6047

Fax: 800-269-0093

International: 402-367-6214

Web site: http://www.kvvet.com/

Email: kvvet@kvvet.com

The information in this article is as accurate as

possible, but you should not take it as absolutely authoritative.

© 2003, 2004 Richard F. Binder

|