Sac-fillers

Following the eyedropper filled fountain pens came the sac fillers, which can

also be called self-fillers.

In these pens the ink was contained inside a flexible rubber sac, which was

attached to a cylindrical stub (or nipple) at the end of the section. The sac

was fully enclosed in the barrel, thus avoiding accidents (compression of the

sac by mistake). I make a distinction between pens where the ink is contained

directly inside the sac

and pens where the small sac is used as a pressure pump. The pressure sac is

used to

“force” air out of the barrel through a breather tube, but the ink

is contained

directly in the barrel, such as in Parker Vacumatic, Waterman Ink-Vue, Wahl

Oxford,

Postal and others.

The method was simple: the sac had to be compressed (deflated) and then released

in

order to produce low pressure inside the sac. This allowed ink to flow into

the sac via

the feed.

The different filling systems focus on two main issues: first is the method

the sac is compressed and released, and the second is how to prevent accidental

squeezing of the sac.

The disadvantages of the sac fillers.

Eventually the sac perished, leaving the filling mechanism inoperative.

The space taken by the sac, the different mechanism and the surrounding clearance

space took a big part of the volume inside the barrel, thus dramatically reducing

the

ink capacity (compared to eyedroppers), and the fumes emanating from the sac

caused

discoloration of the barrel in the long run.

Usually when thinking of sac fillers we think lever fillers or button fillers,

but in fact many other systems were present.

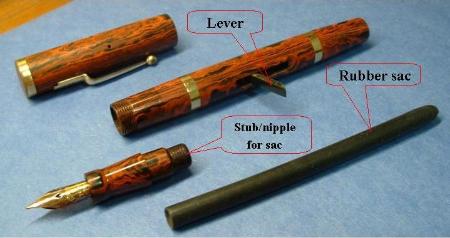

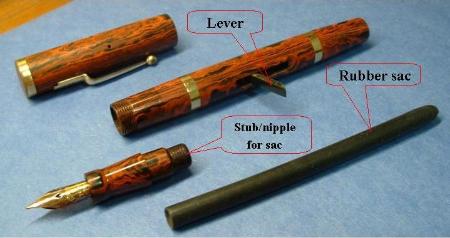

First let’s have a look at a picture meant for those that have not yet

seen the internals of a sac filler. The illustrated pen is a mottled hard rubber

British Swan lever filler from the late 1920’s.

And now to the various sac filling systems:

Crescent fillers

In 1898 Roy Conklin produced the first sac filler in Toledo, Ohio:

The pen had a metal bar inside the barrel attached to a crescent shaped protrusion.

The crescent protruded outside the barrel through a narrow rectangular slit.

When the crescent was pressed the metal bar deflated the sac, and when released

the sac inflated drawing in the ink. And how were accidents avoided: by a ring

with an opening that locked the crescent in place and had to be turned in order

to enable the crescent to be pressed.

Here’s a picture showing a model 30 Conklin from the 1910’s.

The crescent gives was an awkward look to the pen, but this is a pen that won’t

roll off a table!!!. Mark Twain advertised the original Conklin crescent filler

during the beginning of the century and now a modern edition of the crescent

filler, bearing the writer’s name (and signature), is available.

Sleeve fillers

In Sleeve fillers the pressure bar (a flexible metal bar) is fixed inside the

barrel under a large enough opening in the barrel to enable pushing the pressure

bar with a finger.

Thus the pressure bar deflates the sac and when released the ink flows into

the sac. Accident are avoided by a sliding sleeve that covers/uncovers the opening

in the barrel.

The sleeve filling system was used by several companies (Waterman, Le Boeuf

…)

Waterman introduced the sleeve filler in 1910 as it’s first self filling

system using a sac. In 1915 Waterman started producing lever fillers and ceased

sleeve fillers production. In fact we can see in sleeve fillers an early version

of the later aerometric fillers (such as found in Parker 51).

Here’s a picture of the pen with the sleeve moved down

in order to expose the pressure bar:

Coin fillers

Coin fillers also use a pressure bar situated in the barrel under a narrow,

long opening in the barrel. A coin is inserted in the slit and pressed in order

deflate the sac. Accidents are avoided simply because the chance a coin will

find it’s way to the slit without the owner’s intention is virtually

non existent. Several manufacturers (Waterman, Eagle …) used this method.

Waterman even sold its coin-filling pen (1913 – 1914) with a special Waterman

coin to be used with the pen.

The picture is of a No-Name coin filler. The round opening in the middle of

the slit is meant to allow depressing the pressure bar also with the clip-ball

(of a removable clip), in the case you ran out of coins.

Twist fillers

A completely different way to expel the air from the sac is to simply twist

the sac.

In twist filler you have to twist the sac one way in order to expel the air

and then the other way in order to allow inflow of ink.

One of the earliest twist fillers is the Autofiller (Thanks to Len from whom

I obtained this Autofiller)

In the Autofiller pen the sac is attached to the section, feed and nib on

one side while the other side is attached to a plug prolonged in a spindle like

form. One has to manually twist the spindle rod in order to twist the sac.

Accidents are avoided by a blind cap that covers the spindle rod. The blind

cap has to be removed in order to allow the filling procedure.

Another company to use the twist filling method was Swan in their “leverless”

self filling pens (starting from 1932). A knob at the end of the barrel was

connected to a rigid (paddle like) bar inside the barrel. Twisting the knob

caused the sac to be rolled and twisted by this rigid bar. Reverse movement

allowed the sac to inflate and draw in the ink. The drawback was the reduced

ink capacity compared to the side lever filling method due to less efficient

compression of the sac.

The picture is of a Swan machine turned overlay featuring the leverless filling

mechanism:

I think I’ll leave the other sac filling methods (including lever fillers,

Hatchet fillers, button fillers, pneumatic fillers …) for another article

as this one is getting bigger than usual.

|